Meet DeepFleet: Amazon’s new AI model suite that predicts future traffic patterns for mobile robot fleets

Amazon has achieved an extraordinary milestone by deploying its one million robots in global fulfillment and classification centers, solidifying its position as the world’s largest industrial mobile robot operator. This achievement and introduction DeepfleetThis is a groundbreaking basic model designed to enhance the coordination of a large number of mobile robots. After billions of hours of practical data training, these models are expected to optimize robot motion, reduce congestion and improve overall efficiency by up to 10%.

The rise of basic models of robotics

The basic models popular in language and vision AI rely on large dataset learning to adapt to common patterns of various tasks. Amazon is applying this approach to robotics, where coordinating thousands of robots in a dynamic warehouse environment requires predictive intelligence beyond traditional simulations.

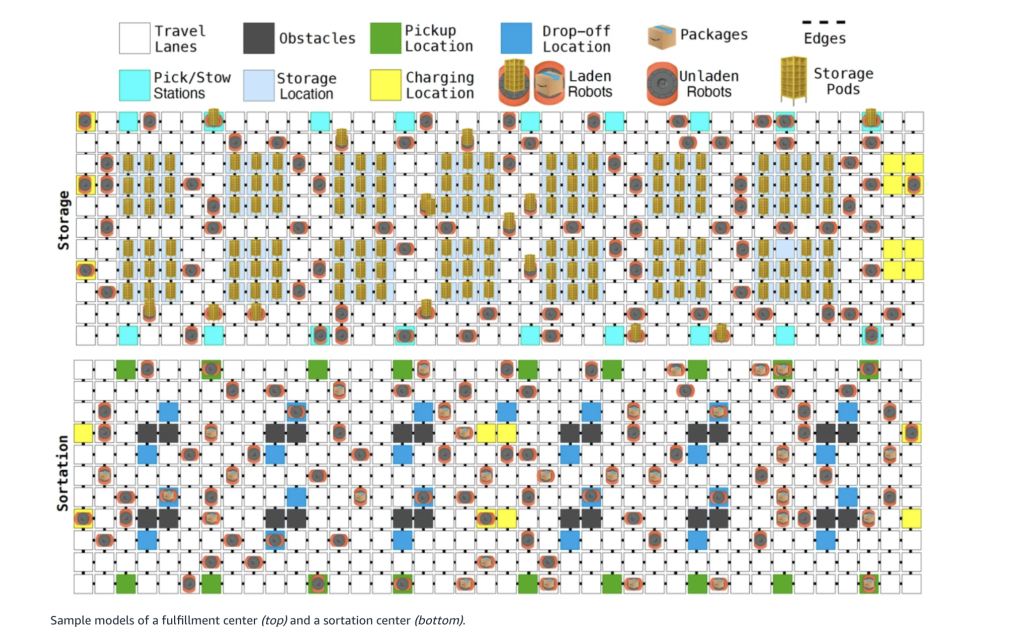

In the fulfillment center, robots deliver stock shelves to human workers, while in the classification facility, they process the parcels for delivery. With hundreds of thousands of fleet numbers, challenges such as traffic congestion and deadlock can slow operations. DeepFleet solves these problems by predicting the trajectory and interaction of robots, thus actively planning.

These models come from various data on warehouse layouts, robot generations, and operational cycles, capturing emerging behaviors such as congestion waves. These data richness (covering millions of bot hours) brings DeepFleet across a variety of situations, just as large language models adapt to new queries.

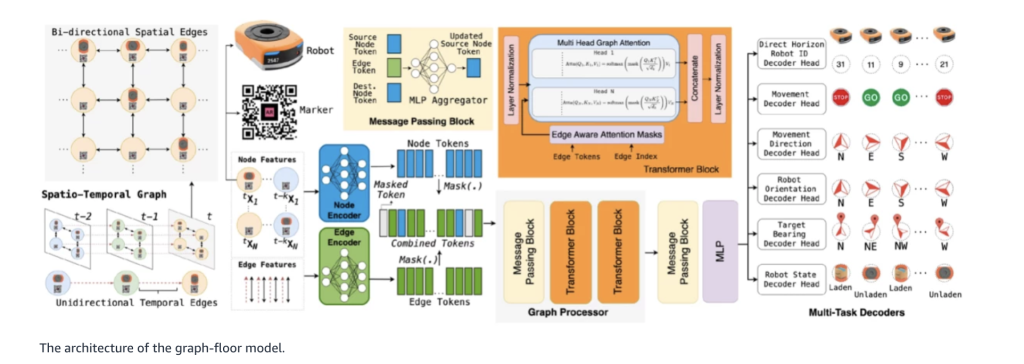

Explore the DeepFleet architecture

DeepFleet includes four different architectures/models, each with a unique inductance bias to model multi-robot dynamics:

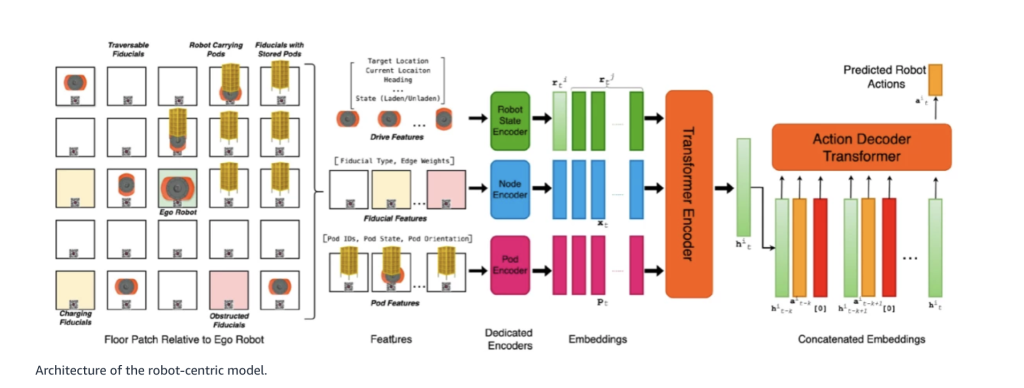

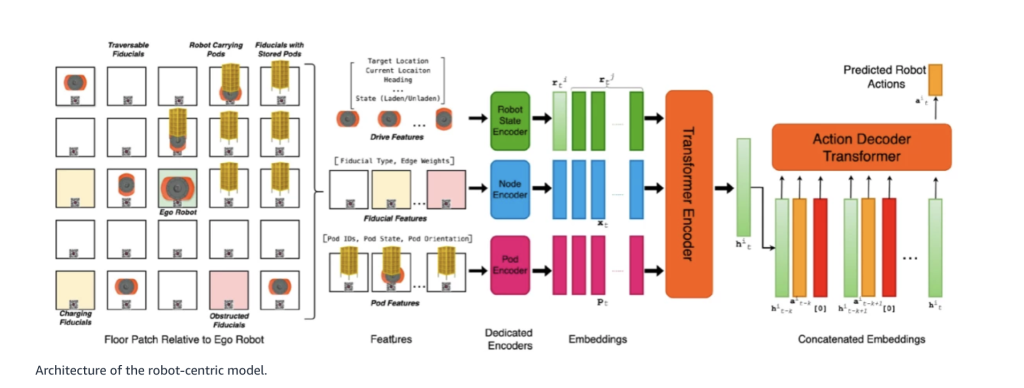

- Robot-centric (RC) model: This autocyclotron transformer focuses on a single robot, using local neighborhood data (e.g. nearby robots, objects, and markers) to predict the next action. It handles the pairing of asynchronous updates and deterministic environment simulators for state evolution. It has 97 million parameters, excelled in evaluation, reaching the lowest position and national forecast errors.

- Robot floor (RF) model: Using cross-attention events, the model combines robot state with global flooring functions such as vertices and edges. It synchronizes decoding actions to balance local interactions and environments within range. It performs excellent in timing prediction at 840 million parameters.

- Image Basics (If) Model: Think of the warehouse as a multi-channel image, which uses spatial features for the time series and convolutional encoding of the transformer. However, it does not perform well, which may be due to the challenges faced when capturing pixel-level robot interactions at scale.

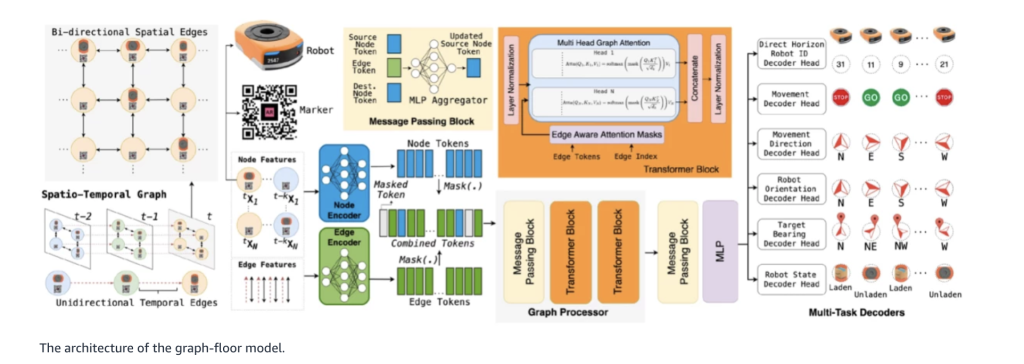

- Graphics (GF) Model: Combining a graphical neural network with a transformer, which represents the floor as a space-time diagram. It effectively handles global relations, with only 13 million parameters predicting actions and states, making it computationally competitive.

These designs differ in time (synchronization vs event-based synchronization) and spatial (local vs global) approaches, allowing Amazon to test the best options for large-scale predictions.

Performance insights and expansion potential

Evaluation of fixed warehouse data uses metrics such as dynamic time warping (DTW) for trajectory accuracy and congestion delay error (CDE) for operational realism. The RC model overall LED, with a DTW score of 8.68 for the position and a 0.11% CDE, while the GF provides strong results at lower complexity.

Scaling experiments prove that larger models and datasets follow the patterns seen in other underlying models, reducing prediction losses. For GF, inference shows that 100 million parameter versions trained in 6.6 million centers can effectively optimize the calculations.

This scalability is key, as Amazon’s massive fleet of robots offers unparalleled data advantages. Early applications include traffic congestion prediction and adaptive routing, and potential task allocation and prevention of impasses.

The impact of the real world on operations

DeepFleet is already enhancing Amazon’s network, which covers more than 300 facilities around the world, including recent deployments in Japan. By increasing the travel efficiency of the robot, it can directly benefit customers with faster packaging processing and lower costs.

Apart from efficiency, Amazon highlights workforce development, with 700,000 employees added 700,000 employees to roles related to robotics and AI since 2019. This integration creates safer jobs by offloading heavy tasks onto the machine.

Looking to the future

As Amazon continues to refine DeepFleet (replace RC, RF and GF variants), the technology can redefine multi-robot systems in logistics. By leveraging AI to predict fleet behavior, it goes beyond reactive control and paves the way for more autonomous, scalable operations. This innovation highlights how the underlying model can extend from the digital realm to physical automation, potentially changing industries that rely on coordinated robotics.

Check Paper and Technology Blog. Check out ours anytime Tutorials, codes and notebooks for github pages. Also, please stay tuned for us twitter And don’t forget to join us 100K+ ml reddit And subscribe Our newsletter.

Asif Razzaq is CEO of Marktechpost Media Inc. As a visionary entrepreneur and engineer, ASIF is committed to harnessing the potential of artificial intelligence to achieve social benefits. His recent effort is to launch Marktechpost, an artificial intelligence media platform that has an in-depth coverage of machine learning and deep learning news that can sound both technically, both through technical voices and be understood by a wide audience. The platform has over 2 million views per month, demonstrating its popularity among its audience.